CNC Maintenance Services from Ram-Z Fab

At Ram-Z Fab, we understand the importance of reliable and efficient CNC maintenance in various industries, particularly in automation, food packaging, and medical testing. Our expertise in CNC maintenance has helped numerous companies achieve high-quality results and improve their manufacturing processes. In this article, we will delve into the world of CNC maintenance, exploring our service offerings, benefits, and why it is an essential service for your industry.

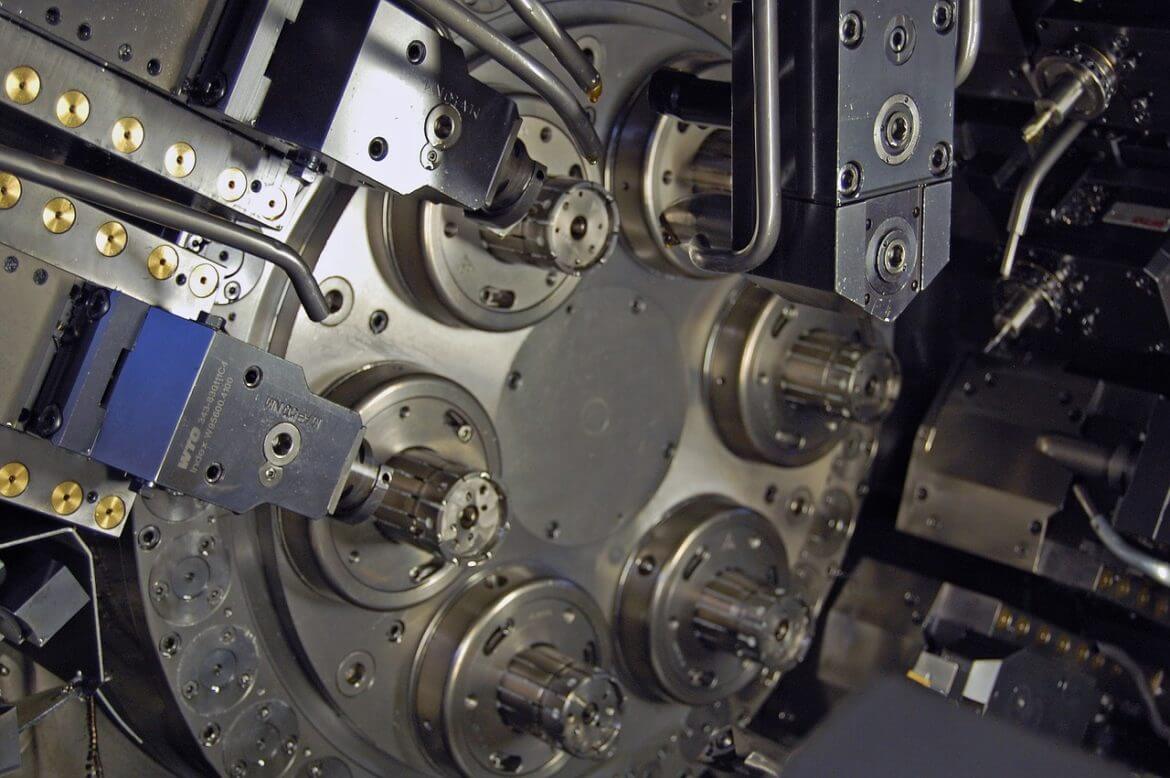

Overview of CNC Maintenance

CNC maintenance is the process of ensuring that your CNC machines are operating at peak performance, reducing downtime, and extending the lifespan of your equipment. Regular CNC maintenance is crucial in industries like automation, where precision and reliability are paramount. By keeping your CNC machines well-maintained, you can ensure consistent product quality, improve efficiency, and reduce the risk of costly breakdowns.

CNC Maintenance Service Types

At Ram-Z Fab, we offer a comprehensive range of CNC maintenance services to meet the diverse needs of our clients. Our services include:

Preventive Maintenance

Our preventive maintenance service focuses on regularly scheduled inspections, adjustments, and replacements to keep your CNC machines running smoothly. This service helps you avoid unexpected breakdowns and ensures that your machines are operating at optimal efficiency.

Corrective Maintenance

When issues arise with your CNC machines, our corrective maintenance service is here to help. Our team of experienced technicians will diagnose the problem, provide a solution, and get your machines back up and running as quickly as possible.

Predictive Maintenance

Our predictive maintenance service uses advanced monitoring and analytics to identify potential issues before they occur. By anticipating problems, we can help you avoid costly downtime and ensure the long-term reliability of your CNC machines.

Why Choose Ram-Z Fab for CNC Maintenance

At Ram-Z Fab, we have been providing CNC maintenance services for over two decades. Our expertise in the field has helped us develop a deep understanding of the needs of various industries. We have worked with numerous companies, including well-known brands like Siemens and Rockwell Automation, to provide customized CNC maintenance solutions that meet their specific requirements.

In the automation industry, for instance, CNC maintenance is crucial for ensuring the reliability and precision of robotic systems. Our preventive maintenance services have helped companies like Fanuc and ABB reduce downtime and improve the overall efficiency of their manufacturing processes.

In the food packaging industry, CNC maintenance is essential for maintaining the high-quality standards required for food-safe equipment. Our corrective maintenance services have helped companies like Bosch and Tetra Pak quickly resolve issues and get their packaging lines back up and running.

If you are looking for a reliable CNC maintenance partner that understands the unique needs of your industry, look no further than Ram-Z Fab. Our expertise, advanced monitoring, and commitment to customer satisfaction make us the ideal choice for your CNC maintenance needs.

GET A QUOTE

Don't let CNC machine issues disrupt your production. Choose Ram-Z Fab for your CNC maintenance needs and experience the difference for yourself. Contact us today to learn more about our services and how we can help you improve the reliability and efficiency of your manufacturing operations.

FAQs

CNC maintenance is the process of ensuring that CNC machines are operating at peak performance, reducing downtime, and extending the lifespan of your equipment. Regular CNC maintenance is critical to prevent unexpected machine downtime and the associated harmful effects.

CNC maintenance is important because it helps ensure that CNC machines are operating at optimal efficiency, reducing the risk of costly breakdowns, and improving product quality.

Common challenges in CNC maintenance include time constraints, excessive machine vibration, and the need for specialized tools and expertise.

CNC maintenance should be performed regularly, with daily, weekly, and monthly tasks to ensure optimal machine performance.

Daily CNC maintenance tasks include inspecting lubricant levels, greasing parts, checking coolant concentration, emptying chip hoppers, and wiping down surfaces.

Weekly CNC maintenance tasks include cleaning the machine shop, checking for lubricant leaks, ensuring cooling fans are working properly, and performing visual inspections.

Yearly CNC maintenance tasks include removing coolant tanks, inspecting and cleaning hydraulic systems, and testing lubrication units.

CNC maintenance should be scheduled based on machine usage hours, with daily, weekly, and monthly tasks to ensure optimal machine performance.

The benefits of CNC maintenance include reduced downtime, improved product quality, and extended machine lifespan.

Effective CNC maintenance can be ensured by following recommended maintenance intervals and procedures, using specialized tools and expertise, and staying up-to-date with the latest technology and best practices.